Process development is a key and critically important component of the pharmaceutical and fine chemical industries. During process development, scientists endeavour to optimise manufacturing performance through the development of improved or new processes for product generation. Continuous flow technology is a new approach to process development, where a chemical reaction or reactions are performed in a continuously flowing stream rather than in batch production. Such continuous flow methods can provide some significant advantages including faster and safer reactions, cleaner products, and easy scale-up.

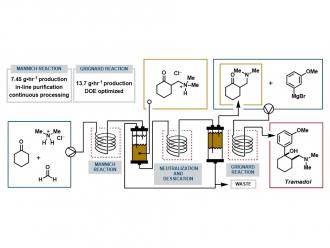

Tramadol (Ultram, Ultracet) is a synthetic opioid analgesic that is frequently prescribed for the treatment of moderate to severe pain, both acute and chronic, and is recognized by a multitude of countries as a crucial medication. As part of a larger project to developing continuous reactors for “on-demand” small-molecule creation, Prof Stephens (Maynooth University) and the Jamison team at MIT have just published a new multioperation continuous-flow platform for the synthesis of Tramadol (Synlett, DOI: 10.1055/s-0039-1690884). These efforts culminated in a rapid production rate of Tramadol (13.7 g per hour). A comparison of process metrics including production rate, environmental factor (E-factor), and space-time yield were used to contextualize the developed platform with respect to established engineering and synthetic methods for making Tramadol. This research is expected to inform future investigations that employ flow processes to create essential medicines used around the world.

https://www.thieme-connect.com/products/ejournals/abstract/10.1055/s-0039-1690884

Figure 1. Schematic of continuous flow synthesis of Tramadol